BENDER IRDH575B1W-435

Welcome to AE Automation Ultra

Delivering cutting-edge automation technologies.

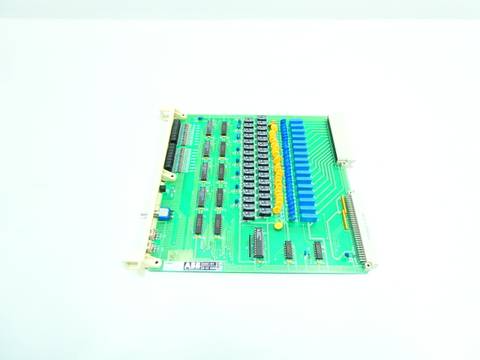

BENDER IRDH575B1W-435: A Key Component for Electrical Engineering

In the ever-evolving world of industrial automation, the importance of reliable electrical components cannot be overstated. One such component that has gained prominence in recent years is the BENDER IRDH575B1W-435. This device plays a crucial role in ensuring the safety and efficiency of electrical systems, particularly in industrial applications and renewable energy sectors.

Understanding the BENDER IRDH575B1W-435

The BENDER IRDH575B1W-435 is a state-of-the-art residual current monitoring relay designed to protect electrical installations from earth faults. It conforms to the technical specifications outlined in IEC60947-2, which governs the safety requirements for low-voltage switchgear and control gear. This compliance not only guarantees high quality but also ensures that the device operates effectively in various environments.

Technical Specifications

According to IEC60947-2, the BENDER IRDH575B1W-435 features:

- Rated Voltage: 230 V AC

- Current Rating: 5 A to 30 A

- Response Time: < 30 ms

- Insulation Resistance: > 1 MΩ

- Environmental Conditions: Suitable for indoor and outdoor applications

- Temperature Range: -25°C to +55°C

These specifications make the BENDER IRDH575B1W-435 an ideal choice for various industrial automation applications, ensuring optimal performance and reliability.

Applications in Industrial Automation

The BENDER IRDH575B1W-435 is particularly useful in environments where safety and efficiency are paramount. Here are some of the key applications:

- Manufacturing Plants: In manufacturing facilities, the monitor relay protects machinery and equipment from electrical faults, reducing downtime and preventing potential hazards.

- Renewable Energy Systems: In solar and wind energy systems, the BENDER relay ensures that any earth faults are detected promptly, allowing for immediate corrective actions that enhance system reliability.

- Healthcare Facilities: Hospitals and clinics require stringent safety protocols. The BENDER IRDH575B1W-435 helps in maintaining safe electrical environments for medical equipment.

Importance in Renewable Energy

As the world shifts towards renewable energy, ensuring the safety and efficiency of these systems becomes increasingly critical. The BENDER IRDH575B1W-435 supports the integration of clean energy solutions by monitoring electrical systems and providing real-time fault detection. This capability not only enhances the lifespan of renewable energy systems but also contributes to their overall effectiveness.

Conclusion

The BENDER IRDH575B1W-435 is an essential component for any industrial automation or renewable energy system. Its compliance with IEC60947-2 standards ensures safety, reliability, and performance. For industries looking to enhance their electrical systems with high-tech solutions, investing in the BENDER IRDH575B1W-435 is a step towards achieving industrial intelligence.

For more information on electrical engineering and automation technologies, visit the International Electrotechnical Commission. Also, check out our other resources at fanucultra.com to stay updated on the latest in industrial automation.