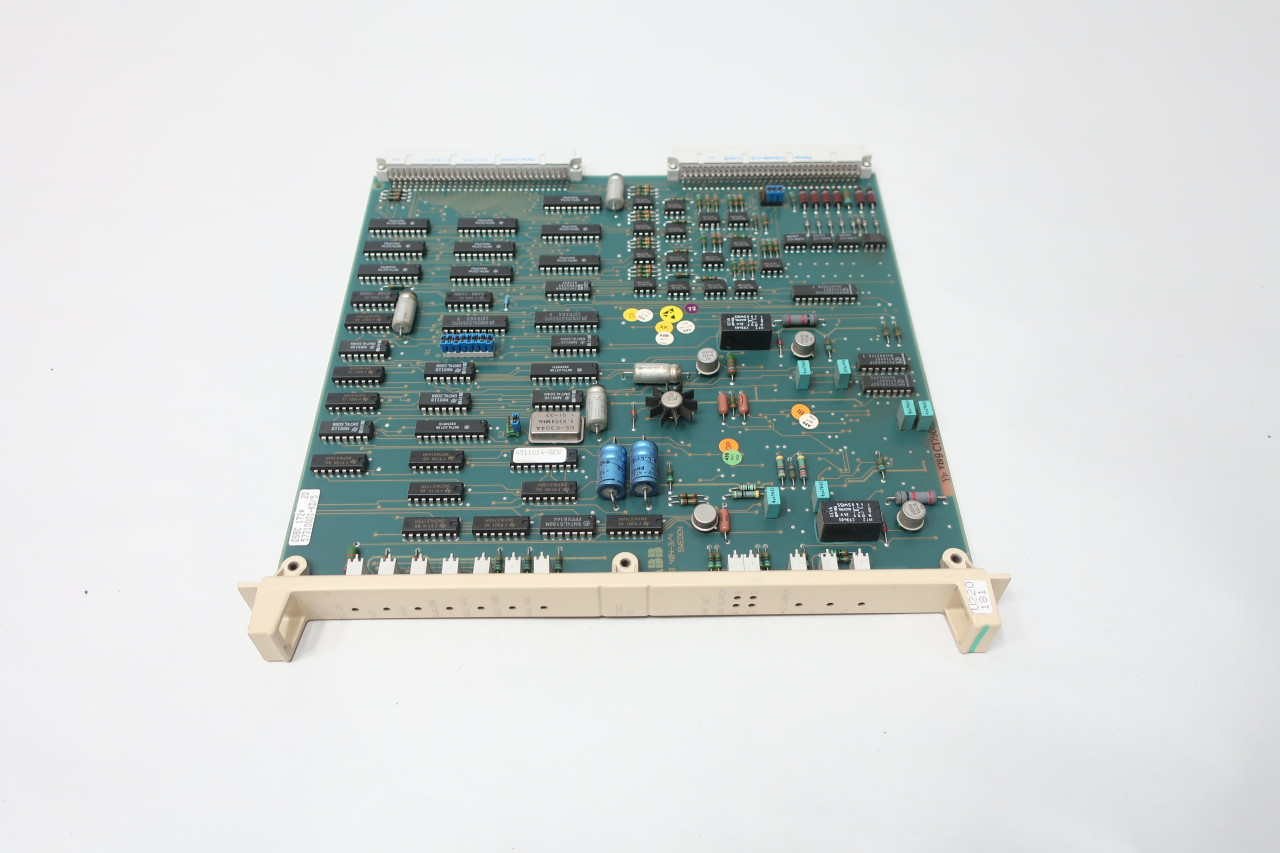

YOKOGAWA NFCP100-S00 S3

Welcome to AE Automation Ultra

Delivering cutting-edge automation technologies.

The YOKOGAWA NFCP100-S00 S3: A Game-Changer in Electrical Engineering

The YOKOGAWA NFCP100-S00 S3 is a pivotal development in the realm of electrical engineering, particularly within industrial automation and renewable energy sectors. As industries continue to embrace the fourth industrial revolution, the need for sophisticated control systems has never been greater. The NFCP100-S00 S3 not only meets these demands but also sets a new standard for reliability and performance.

Importance of Electrical Engineering in Automation

Electrical engineering is the backbone of automation technology. It integrates various elements, including control systems, sensors, and actuators, to create seamless operational processes. The YOKOGAWA NFCP100-S00 S3 exemplifies how electrical engineering can drive innovation and efficiency. With its advanced features, this device plays a crucial role in ensuring systems operate smoothly and reliably, thus enhancing productivity and minimizing downtime.

Technical Specifications (IEC60947-2)

According to the IEC60947-2 standards, the YOKOGAWA NFCP100-S00 S3 is designed to ensure safety and performance in electrical installations. Some of the key technical specifications include:

- Rated Operational Current: Capable of handling a wide range of currents, ensuring versatility in various applications.

- Voltage Rating: Designed to operate within specified voltage ranges, adhering to international safety standards.

- Temperature Range: Built to withstand extreme environmental conditions, making it suitable for diverse industrial settings.

- Protection Class: Features a robust construction that provides excellent protection against dust and moisture ingress.

- Certification: Complies with international standards, ensuring reliability and safety in operation.

Applications in Industrial Automation

The YOKOGAWA NFCP100-S00 S3 is widely utilized in various industrial automation applications, including:

- Process Control: Essential for maintaining optimal operation parameters in manufacturing processes.

- Robotics: Plays a key role in controlling robotic systems for enhanced precision and efficiency.

- Data Acquisition: Facilitates real-time data gathering, crucial for monitoring and improving operational performance.

- Safety Systems: Integral in implementing safety measures to prevent equipment failures and accidents.

Impact on Renewable Energy

In the renewable energy sector, the YOKOGAWA NFCP100-S00 S3 is instrumental in optimizing energy generation and distribution. It supports various applications, such as:

- Wind Energy: Controls and monitors wind turbines, ensuring efficient energy capture and grid integration.

- Solar Power: Manages solar inverter systems for effective energy conversion and distribution.

- Smart Grids: Enhances the functionality of smart grids, facilitating the integration of renewable sources into the energy mix.

Conclusion

The YOKOGAWA NFCP100-S00 S3 is a testament to the advancements in electrical engineering and its critical role in industrial automation and renewable energy. By adopting such high-tech solutions, industries can achieve greater operational efficiency, safety, and sustainability. For more information on automation technologies, visit fanucultra.com or check out the resources from the International Electrotechnical Commission.